Typical bioaugmentation products consist of blends of several strains of microorganisms, usually bacteria or fungi. The organisms are isolated from nature and are not genetically altered in any way. They are selected on the basis of accelerated reproduction rates and their ability to perform specific functions, such as good floc-forming capabilities to enhance settling or the ability to degrade specific compounds. The products are sold in a variety of forms, with dried organisms on a bran carrier and liquid products being the two most common.

Product selection for a particular application is based on a combination of laboratory treatability studies and field experience in similar applications. Plant samples of wastewater influent and aeration basin biomass are sent to the laboratory for product screening and treatability work.

Typically, one week is required to complete the laboratory work. In some cases, where the plant is in danger of permit violation, program implementation must begin prior to lab work completion. In these cases, the experience from similar application is critical in determining the initial course of action. The lab work will be run concurrently with program implementation and utilized to make adjustments in the program, if necessary.

More Than Just Products

Successful bioaugmentation requires total system management. If the microbiological population can be viewed as a workforce, then the consultant or system manager is responsible for keeping the workforce productive.

The system manager must provide an acceptable work environment by controlling the key system parameters such as PH, temperature and oxygen levels. He must compensate them with nutrients to ensure good growth and a healthy population. He has to know when to lay-off workers through wasting to keep the population young and vital. Finally, the successful system manager knows when to hire new workers to provide special skills not found in his workforce. Bioaugmentation is the mechanism to provide these skilled workers.

A critical part of the success of a bioaugmentation program is proper application. Because every system is unique, it is essential that products are properly applied. Bioaugmentation programs should be implemented with the help of surveying the total system, assessing the best solution to the problem and documenting the impact of the program. Simply dumping a product into the influent is not bioaugmentation.

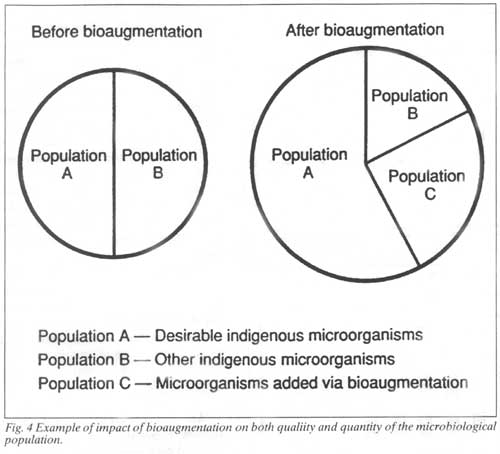

The purpose of bioaugmentation is to facilitate a gradual shift in the microbial population, not to totally replace the existing biomass. The population shift must be accomplished in a planned and controlled manner to maintain the integrity of the microbial ecosystem. Over-feeding the selected microorganism could result in a biomass no better equipped to handle the broad range of compounds in the influent that the original population.

Proving The Results

The greatest difficulty in gaining acceptance of bioaugmentation as a valid technology is proving cause and effect of the addition of the specific organisms. Classical science would instruct the customer to run a controlled experiment in his plant, concurrent with the bioaugmentation program. In reality, this is rarely possible because a few waste plants have identical, separate, side-by-side systems to allow a rigorous head-to-head trial. Secondly, bioaugmentation is frequently a last ditch effort to save a system form “shutting down” and sending the plant into permit violation. Many times, in addition to bioaugmentation, other system parameters are changed, introducing new variables into the equation.

To effectively document the impact of the bioaugmentation program, plant data for several months prior to the program should be plotted and compared to the data after program implementation. For a bioaugmentation trial to be meaningful, the trial must be run three to five times the holding time for a once-through lagoon system, or four to six sludge ages (mean cell retention time) for an activated sludge system.

Figures 5 and 6 illustrate two examples of the impact of bioaugmentation at two paper mill waste treatment plants. The paper mill in the first case was facing permit violations for BOD in the effluent. Figure 5 shows the improvement in BOD removal after the application of a bioaugmentation program. Within statistical significance, all operating variables, such as incoming BOD and flow, were constant before and after the application of the bioaugmentation program.

In the second example, the mill was experiencing both BOD and total suspended solids (TSS) excursions. To maintain TSS compliance, large amounts of polymer were being fed to the final clarifiers. Figure 6 shows the impact of the bioaugmentation program in reducing polymer usage.

Reprinted from Environmental Protection, October 1992