Toll Free: 800-613-6803

Email: water@tramfloc.com

< Previous Page

|

|||

|

.....The

defoamer was tested with ferric chloride and polymer doses of 55 mg/L

and 1.5 mg/L, respectively. After ballasted flocculation, treated

effluent samples were decanted into a sample bottle and shaken. Significant

foam was observed on the sample surface. .....The

project team then tested the vegetable oil by adding 5 pL of it to

ballasted flocculation effluent. The sample was shaken and allowed

to set. This process was repeated until the foam dissipated and did

not return, which occurred when 20 pL of vegetable oil was added (this

equates to approximately 20 mg/L). Sodium hypochlorite and sodium

bisulfite were also added to the sample. Slight foaming was observed

when the sample was shaken, but the foam dissipated almost immediately.

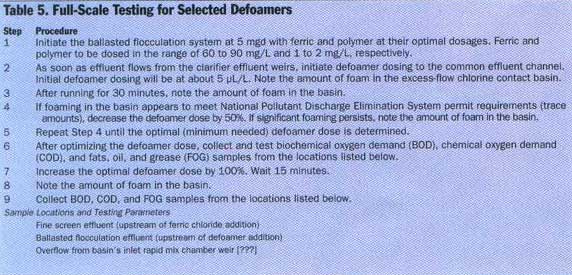

.....All jar testing was conducted using plastic equipment (jar testing vessels, sample containers, etc.) because plastics are most likely to support worst-case foaming conditions (surface tension, static charge, etc’ see Table 4, p. 34). The project team hoped that lower dosages of defoaming agent would be effective in the full-scale ballasted flocculation system, given its concrete chambers and stainless steel equipment, but full-scale testing at a flow rate of 7600 m3/d (2 mgd) showed that the higher doses were necessary. .....So, the project team contacted other chemical companies to find several comparable defoamers that could control the foam at lower dosages and to determine the best place to add defoamer. Five locations were reviewed: before the ferric chloride dosage point, in the ballasted flocculation basin, at the ballasted flocculation effluent discharge point, after chlorination at the excess-flow chlorine contact basin, and after dechlorination but before blending with the plant’s effluent. ..... More than 10 defoaming agents were tested on ballasted flocculation effluent with doses of 75 mg/L and 1.5 mg/L of ferric chloride and polymer, respectively.

|

.....Sodium

hypochlorite and sodium bisulfite were added to each jar test

to ensure the disinfection and dechlorination process would not affect

results. Testing showed that

Tramfloc® 1110, Chemco DF-410, and Neo Solutions NS-8454 suppressed foam at doses of 1 to 5 mg/L, with Tramfloc® 1110 yielding the best results. ..... In addition, it seems that the best application point is in the excess-flow chlorine contact basin, after either disinfection or dechlorination. Each defoamer is a silica emulsion, which may not affect the plant’s BOD, or fats, oil, and grease limits and, therefore, its NPDES permit. The project team then did full scale testing using primary basin effluent at a 19,000-m3/d (5-mgd) flow rate to verify jar test results and determine the optimum dose (see Table 5, above). The jar test procedure was also modified to incorporate full-scale testing. During this testing, the project team noted that all three defoamers prevented foam from generating at points of impact and turbulence. The optimum dosage rates are: • Tramfloc® 1110 at 1.25 mg/L, • Chemco DF-410 at 3.0 mg/L, and • Neo Solutions NS-8454 at 5.0 mg/L. Conclusions John Keller is a project engineer and Matthew Schultze is a project manager at Black & Veatch Corp. (Kansas City, Mo.)

|

||